Glue Laminated Beams (GLBs), made from bonded wood veneers, offer exceptional strength and stability for construction. Cost factors include raw material procurement, lamination techniques, quality control, and regional availability, with high-density timber generally more expensive. Installation costs vary by project scale, complexity, location, labor, and material market fluctuations. For detailed insights and personalized quotes, visit unalam.com or contact (607) 369-9341.

“Exploring the financial landscape of glue laminating beams? This comprehensive guide unveils the intricate details behind calculating total costs. From comprehending the fundamentals of these innovative construction elements to dissecting material, labor, and installation expenses—we demystify the pricing. Whether you’re an architect, engineer, or contractor, understanding the Glue Laminated Beam Cost is pivotal for successful project budgeting. Dive into this insightful article to navigate the cost breakdown with precision.”

- Understanding Glue Laminated Beam Basics

- Material Costs: Factors and Calculations

- Labor and Installation Expenses Breakdown

Understanding Glue Laminated Beam Basics

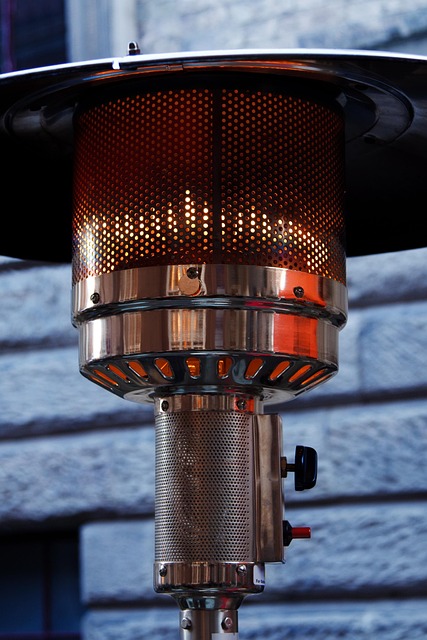

Glue Laminated Beams, also known as GLB or industrial timber lamination, are engineered structural components crafted by bonding together multiple layers of wood veneers with strong adhesives. This innovative process creates beams with exceptional strength and dimensional stability, making them a popular choice for construction projects demanding high-performance structural elements. The precision involved in their manufacturing ensures consistent quality, which is a significant advantage over traditional solid timber beams.

Understanding the basic principles behind glue laminating beam cost is crucial when estimating project expenses. Beam lamination costs breakdown includes raw material procurement, meticulous lamination processes, and stringent quality control measures. These factors collectively determine the final price point. If you’re curious about industrial timber lamination rates or want to explore more about this advanced wood product, visit us at unalam.com to gain detailed insights into glue laminating beam cost and its benefits.

Material Costs: Factors and Calculations

Material costs play a significant role in determining the overall price of glue laminated beams, making them a crucial aspect for construction projects to consider. The expense of these beams can vary widely based on several factors, including the type and quality of wood used, lamination techniques, and regional availability. High-density timber, for instance, will generally command a higher Glue Laminated Beam Cost compared to more readily available softwoods.

Calculating material expenses further involves considering the intricacies of lamination processes. Advanced worldwide timber lamination rates often reflect sophisticated manufacturing methods that enhance structural integrity while potentially reducing glue beam costs through optimized resource utilization. To explore cost-effective glued wood solutions, don’t hesitate to reach out to industry experts. Give us a call at (607) 369-9341 for personalized insights and guidance tailored to your project requirements.

Labor and Installation Expenses Breakdown

The cost of installing glue laminated beams can vary significantly depending on several factors, including the project’s scale, complexity, and location. Labor and installation expenses are substantial components of the overall price tag. Skilled laborers with expertise in structural engineering and wood lamination are required for accurate beam placement and securing. This specialized knowledge ensures the beams meet safety regulations and structural integrity standards.

In addition to labor, material costs contribute to the final price. Commercial glue laminated beam pricing fluctuates based on market demands, timber availability, and global logistics. The worldwide timber lamination rates reflect these dynamics, influencing the overall cost guide for timber lamination. For accurate quotes, it’s advisable to consult with local suppliers or visit us at 18 Clifton St, Unadilla, NY 13849 anytime for personalized assessments aligned with your project’s unique needs.

When considering the total cost estimation for glue laminated beams, understanding the underlying factors is key. By breaking down material costs, labor expenses, and installation, you can gain a comprehensive view of what contributes to the overall price. With this knowledge, you’re equipped to make informed decisions regarding your construction project’s budget and ensure cost-effectiveness while utilizing high-quality glue laminated beams.